About Building & Construction Making Line

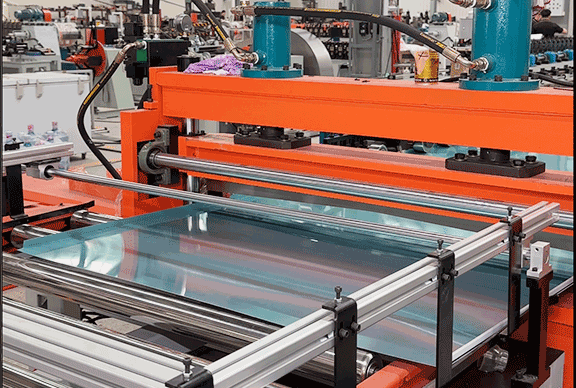

We engineer robust, high-output roll forming lines for the demanding construction industry. Our solutions transform galvanized steel and other materials into durable structural components, from ceiling grids to wall panels. Built for reliability, our machines ensure the production of precise, weather-resistant profiles that meet stringent industry standards.

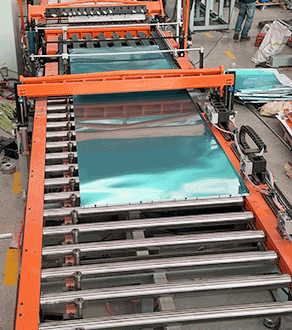

High-Speed Production Lines for Metal Ceiling T-Grids & Furring Channels

Achieve high-volume production of ceiling suspension system components, including T-bars, main runners, and furring channels. Our lines are optimized for speed and precision, ensuring consistent profiles for fast and easy installation. Integrated punching systems can create interlocking features and suspension holes in a single, continuous process..

What type of ceiling profiles do you need?

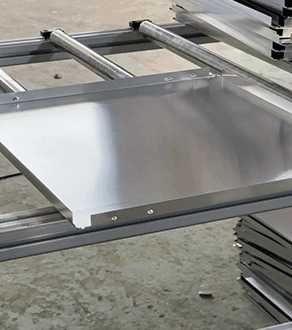

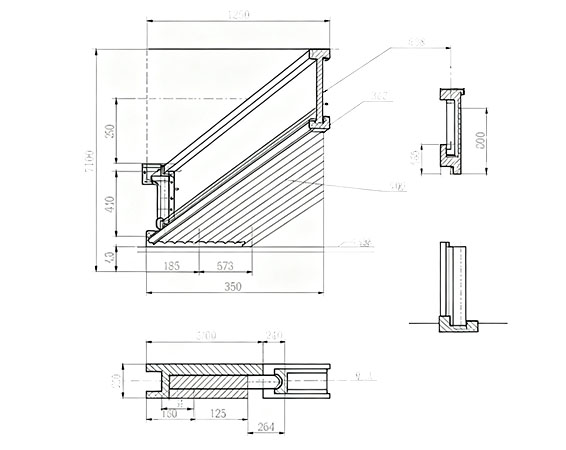

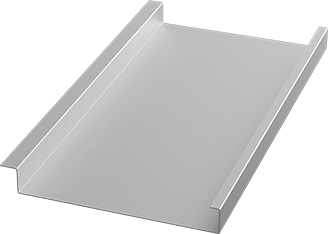

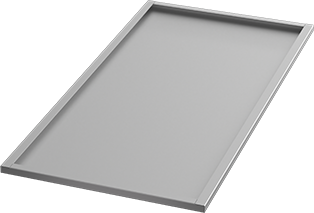

We can customize according to your requirements based on the load-bearing capacity, dimensions, and specifications needed for ceiling aluminum profiles. Here is a showcase of customizations we have made for ceiling factories.

Technology That Drives Your Competitive Edge

Our production lines are not just assemblies of standard parts; they are integrated systems featuring advanced technologies designed to maximize your productivity, flexibility, and profitability.

Auto-Cut Technology for Ceiling Profiles

Experience flawless production with our automated cutting system:Laser-Sharp Accuracy - Perfectly square cuts every time. Flying Cut Technology - Continuous operation, zero downtime. Digital Length Control - Consistent dimensions along entire production run

Perfect Hydraulic System

Armdax punch precise holes for clips and connectors directly in the forming process. Eliminate costly secondary operations. Hydraulic force delivers clean, burr-free holes in heavy-duty steel, ensuring perfect structural integrity. And Easily adapt punching patterns for different shelf models with quick tooling changes, which perfect for custom orders.

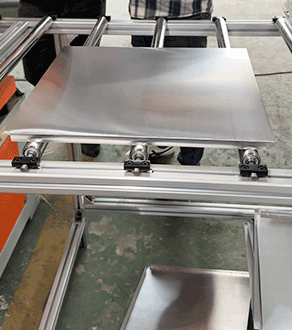

Precision Hemming for Ceiling Profiles

Our advanced hemming process creates flawless edges on ceiling profiles, delivering: Our advanced hemming process creates flawless edges on ceiling profiles, delivering: Ultra-Smooth Finishes - Eliminates sharp edges for safer handling and installation.Reinforced Structure - Enhances durability while maintaining clean visual lines. Perfect Integration - Ensures seamless connections between profile components

Engineered for Peak

Performance and Precision

Every component and parameter of our production line is designed and specified to deliver consistent, high-quality output.

| Product Material:Metal | Material Thickness:0.2-5mm Optional |

| Product Width Range:Servo Adjustable | Margin of error:±0.3mm |

| Drive System:Yaskawa Servo Motor Driven | Form speed:Up to 30m/min |

| Control System:Mitsubishi PLC or other Optional | Roller material:Cr12MoV |

Download Full Technical Proposal

Download Full Technical ProposalFrom Steel Coil to Shelf Panel

100,000 +

Success Cases

Finished column products

Finished column products Finished column products

Finished column products

Finished column products

Ready to Optimize Your Production?

FAQS

Q: What is the maximum speed and output of your machines?

A:

Armdax roll forming machines have a line max speed up to 35 meters per minute. The actual output depends on the profile complexity and operator efficiency.

Q: What kind of control system do you use?

A:

We use internationally renowned PLC systems (like Siemens or Mitsubishi) with a user-friendly touchscreen interface. This allows for precise control over speed, length, and production count.